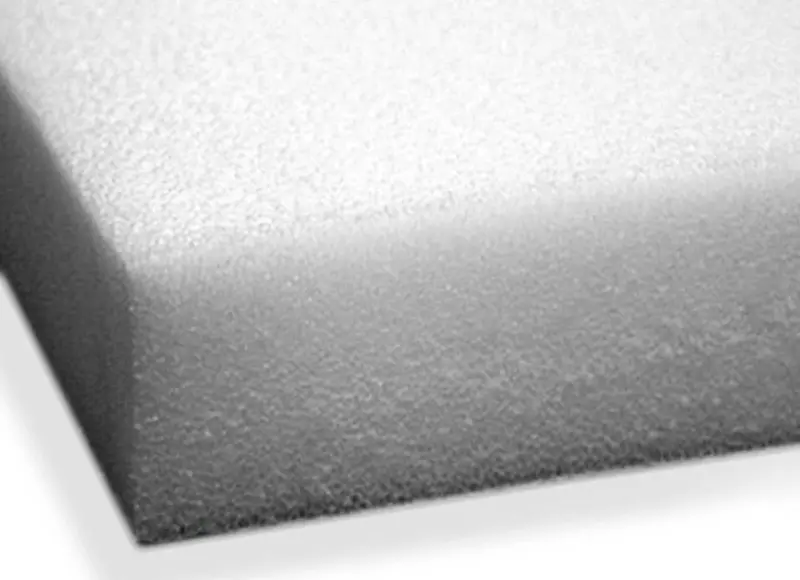

Polyethylene Foam is a combination of compressed polyethylene and very fine air bubbles, which, due to its cellular density, is the best insulation against cold, heat, moisture, and sound. It comes in a variety of thicknesses and densities.

This product comes in densities of 25 to 30 kilograms per cubic meter.

Rolled polyethylene foam is produced in thicknesses of 1,2,3,4,5,6,8,10 mm and a variety of colors.

It is one of thousands of petroleum derivatives, which is much cheaper than other petroleum products.

Polyethylene foam is a type of solid material that is closed-cell and does not absorb moisture and does not grow mold or mildew.

Applications:

Automotive industry

Production of packaging foam

Production of backpacks and helmets

Production of medical and sports mattresses

All types of sports flooring

Home decoration

Production of park and amusement park spaces

Insulation of petrochemical pipes and refineries

Wrestling and judo mattresses, cross-country and gymnastics

Insulation of water pipes, tanks, and ventilation ducts

As a shock absorber in the packaging industry

Insulation of floors, walls, under parquet, and roofs of sheds

Specifications:

Non-toxic

Very flexible

Resistant to corrosion

Lightweight and easy to carry

Suitable for humid environments and sub-zero temperatures

Resistant to ozone and ultraviolet

Resistant to pressure and high impact strength

Resistant to fungal and biological contamination

Polyethylene foams are less expensive than elastomeric insulation

They are easy and quick to install, saving time and installation costs